PTFE Graphite Reboiler

Price 175000 INR/ Piece

PTFE Graphite Reboiler Specification

- Type

- Graphite Tube Heat Exchanger

- Material

- PTFE lined graphite

- Working Temperature

- -20C to +220C

- Density

- 2.3 Gram per cubic centimeter(g/cm3)

- Corrosion Protection

- Excellent chemical resistance

- Tensile Strength

- 20-30 MPa

- Thickness

- Standard and customizable

- Melting Point

- 327C

- Size

- Available in various sizes

- Width

- Customizable

- Length

- Custom length per requirements

PTFE Graphite Reboiler Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 1 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- As per order

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- All India

About PTFE Graphite Reboiler

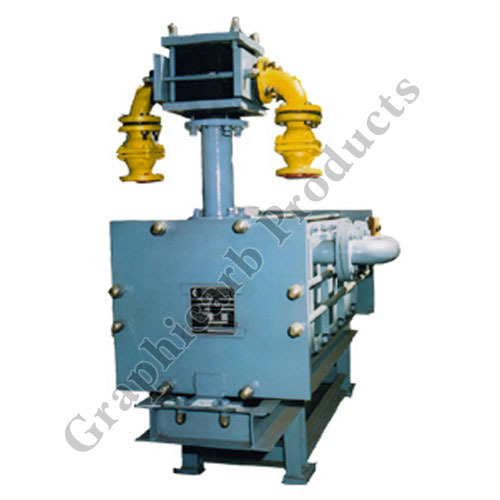

We take pride to introduce ourselves as a reputed manufacturer, supplier and exporter of Graphite Reboiler. Our offered re-boilers can handle corrosive fluid on both service as well as process side. Available in different specifications, these industrial re-boilers are used in multiple effect evaporators due to its superior features. Manufactured with industry laid guidelines, these re-boilers are available in various technical specifications and also in customized range to meet the specific demands of our patrons. This Graphite Reboiler is known for its following features:

- Thermal shock resistance

- Easy to install

- Optimum performance

- Corrosion resistance

Other Information:

We are one of the leading manufacturers of wide range of graphite process equipment which also includes Graphite Reboilers that can handle corrosive fluid on both service as well as process side. Available in different shapes and sizes, these re boilers are used in multiple effect evaporators. We also consider the specifications provided by client regarding the shapes and loading conditions.

With the constant support of our expert team, we are engaged in offering a huge assortment of Heat Exchangers. This graphite heat exchanger is highly efficient in handling chemicals that are corrosive in nature. Due to its high thermal conductivity and corrosion resistance, graphite serves as the ideal material for the construction of heat transfer equipment.

Features of graphite Reboilers

- Fully made of graphite on both process as well as service sides.

- MOC on service side being Graphite makes it possible to use corrosive fluids/gasses as utility medium.

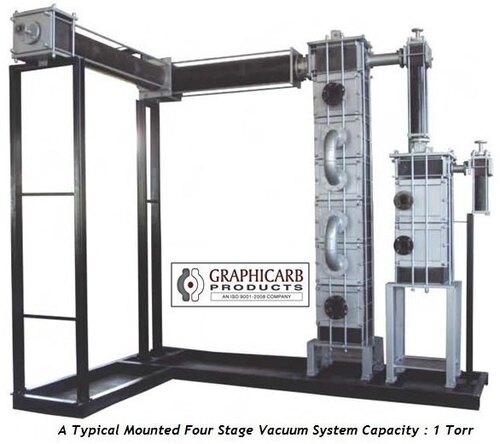

- Multiple units mounted one on another makes it possible to increase surface area of the equipment up to 90 meter square.

- Simple robust and easy to install tough construction.

- Multiple passes can be provided on service sides. .

- Graphite has high compressive strength so metal plate apply compressive load on graphite

- Simple design and easy dismantling as compared to circular blocks.

- Flexibility of adding more blocks to increase heat transfer area.

- Easy cleaning because of short channels.

- Short channel lengths increases turbulence as a result avoids frequent deposits or fouling as compared to shell & tube type heat exchanges of same dimensions, cubical block type heat exchanger provides 2 to 5 times more heat transfer.

- Working conditions : Upto 5kg / cm2 pressure.

- Resistant to thermal shock.

Superior Chemical Resistance

Engineered with PTFE-lined graphite tubes, this reboiler excels in the harshest chemical environments. The unique material combination provides a formidable barrier against corrosive substances, ensuring the longevity and stability of your heat exchange process. This makes it an ideal choice for chemical, pharmaceutical, and other demanding process industries.

Customizable and Reliable Design

The PTFE Graphite Reboiler offers remarkable flexibility in installation and usage, supporting both horizontal and vertical mounting and lengths of up to 6 meters. Customizable widths and thicknesses allow seamless integration into various plant configurations, while rigorous leakage protection guarantees safe and efficient operation even at pressures up to 6 bar.

Low Maintenance and Easy Cleaning

With its smooth, non-stick surface and durable PTFE-lined graphite tubes, this heat exchanger significantly reduces maintenance frequency. Its design allows quick and effortless cleaning, ensuring minimal downtime and consistent performance without complex servicing. High chemical resistance further minimizes the risk of fouling and operational interruptions.

FAQs of PTFE Graphite Reboiler:

Q: How is a PTFE Graphite Reboiler typically installed in a chemical processing plant?

A: This reboiler can be installed either horizontally or vertically, depending on your plant layout and process requirements. Its customizable size and mounting flexibility ensure that it adapts easily to available space and operational needs.Q: What are the main benefits of PTFE-lined graphite tubes in the reboiler?

A: PTFE-lined graphite combines exceptional heat conductivity with superior chemical resistance, resulting in efficient heat exchange, longer equipment life, and reduced risk of chemical corrosion or leakage. The nonstick surface also allows for easier cleaning and maintenance.Q: When should I consider using a PTFE Graphite Reboiler for my process?

A: A PTFE Graphite Reboiler is ideal whenever your heat exchange process involves aggressive chemicals or requires frequent cleaning, high thermal performance, or reliable leakage protection. It is particularly suitable for pharmaceutical, chemical, and similar industries.Q: Where can the PTFE Graphite Reboiler be used within my plant?

A: It is highly versatile and can be used in a wide range of heat exchange applications, such as distillation columns, reactors, condensers, and other critical points where efficient, corrosion-resistant heat exchange is needed.Q: What is the process for cleaning and maintaining this reboiler?

A: Thanks to its smooth, non-stick PTFE surface, simple rinsing and standard chemical cleaning are sufficient. Frequent, complex maintenance is not required, as the design inhibits fouling and allows easy inspection.Q: How does the high-stress PTFE sealing technology improve leakage protection?

A: This advanced sealing ensures reliable containment of chemicals even under high pressure (up to 6 bar). The seals are designed to withstand thermal cycling and mechanical stress, minimizing the risk of leaks over time.Q: What customization options are available for this reboiler?

A: Width, length (up to 6 meters), thickness, and mounting position can be customized according to your specific application needs. Contact the manufacturer or supplier in India to discuss your requirements and integration options.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PTFE Products Category

|

GRAPHICARB PRODUCTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry