PTFE Graphite Vacuum Systems

Price 300000 INR/ Piece

PTFE Graphite Vacuum Systems Specification

- Type

- Vacuum System

- Material

- PTFE with Graphite

- Working Temperature

- -200C to +260C

- Density

- 2.3 Gram per cubic centimeter(g/cm3)

- Corrosion Protection

- Excellent (Inert to most chemicals, acids, alkalis)

- Tensile Strength

- 10 - 20 MPa

- Thickness

- 1 mm to 5 mm

- Melting Point

- 327C

- Size

- Customizable as per requirement

- Width

- Up to 1000 mm

- Length

- Up to 10 meters

PTFE Graphite Vacuum Systems Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 1 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- As per order

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2015

About PTFE Graphite Vacuum Systems

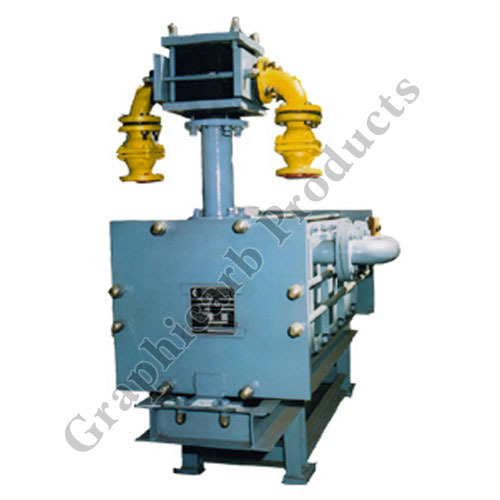

Abiding by the ethical industry norms, our organization is instrumental in offering an optimum array of Graphite Vacuum Systems. Our offered industrial vacuum systems consist of efficient graphite condensers, graphite inter-connecting piping and graphite ejectors and all these components enhance the performance of our product. Owing to their low steam consumption feature, these products are highly demanded and acknowledged by the customers. These Graphite Vacuum Systems come with ejector sizes ranging from 25 nb to 300 nb and are capable of creating vacuum up to 0.5 torr.

Application areas:

- De-carbonating brewery water

- Creating chemical process vacuums

- Perfume concentration

- Distillation process

Other Details:

Complete skid mounted vacuum system is a combination of Steam Jet Ejector, Condenser and Internal piping all of Graphite. In Steam Jet Ejector which is based on the ejector-venturi principle, steam issuing through an expanding nozzle has its pressure energy converted to velocity energy.A vacuum is created and the high velocity of steam entrains air or gas and the mixture of gas and steam enters the converging end of the venturi, passes through the diffuser where its velocity energy is converted into pressure sufficient to discharge against a predetermined back pressure.

This combinations is introduced in a Condenser made of Graphite and maximum vapor is condensed and is let out of the condenser unit through outlet connection provided. All the vapors are condensed into its liquid stage and what leaves the system is just Pure Air having vapors in PPM.

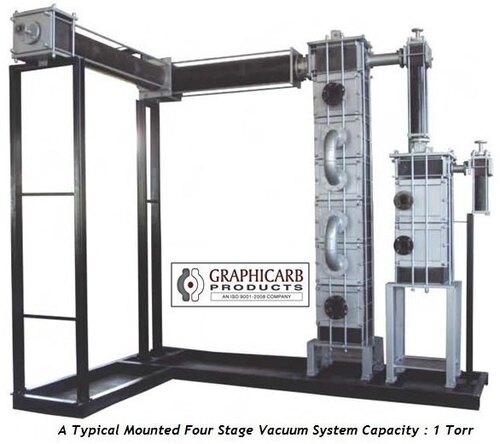

Multiple stage vacuum system

Staging of ejectors becomes necessary for economical operation as the absolute suction pressure decreases. Based upon the use of auxiliary equipment, two and three-stage ejectors can either be condensing or non-condensing types.

Two-Stage Steam Jet Ejector Principle of Operation

Two-Stage Steam Jet Ejectors have the same general field of application as the single stage units. They handle both condensable and non-condensable gases or vapors, as well as mixtures of the two. The general operating range is between 5" Hg. abs. and 3 mm Hg. abs.

Three-Stage Steam Jet EjectorPrinciple of Operation

Three-Stage Ejectors are recommended for applications where a two-Stage unit will not provide low enough suction pressure economically. Applicable range is from 26 mm Hg. abs. to 0.8 mm Hg. abs. Three-Stage Condensing Steam Jet Ejectors consist of a booster ejector, a condenser, and a Two-Stage Ejector consisting of a high-vacuum ejector, inter-condenser, and low vacuum ejector. In some applications another condenser (after-condenser) can be used at the low vacuum ejector discharge.

This way, through multiple stages vacuum system, All the vapors are condensed into its liquid stage and what leaves the system is just Pure Air having vapors in PPM.

|

Applications |

|

|

|

Water treating by degasifying. |

|

|

|

|

|

Impervious Graphite is the material which can handle highly corrosive vapors received from the reactors. |

FOR MORE DETAILS PLEASE LOG ON TO

Exceptional Chemical and Thermal Resistance

PTFE Graphite Vacuum Systems deliver remarkable durability in highly corrosive environments, resisting most acids, alkalis, and chemicals. The blend of PTFE with graphite ensures high stability across extreme temperatures and pressures, making them ideal for rigorous applications such as chemical processing and vacuum pumping operations.

Flexible Sizing and Custom Solutions

With customizable options for width, length, and thickness, these vacuum system components accommodate unique requirements in various setups. Available as gaskets, sheets, or precision-cut designs, they provide versatility in installation, ensuring exact fits and optimal performance for diverse industrial needs.

FAQs of PTFE Graphite Vacuum Systems:

Q: How are PTFE Graphite Vacuum Systems used in vacuum pumps and pharmaceutical processing?

A: These systems serve as gaskets or sealing components to prevent leaks and contamination in vacuum pumps and pharmaceutical processing equipment, maintaining integrity under variable pressures and a wide range of temperatures.Q: What are the benefits of using PTFE Graphite material over traditional sealing options?

A: PTFE Graphite offers superior chemical inertness, excellent corrosion resistance, and robust mechanical strength, outperforming many conventional sealants. It handles demanding conditionsincluding aggressive chemicals and thermal extremeswithout compromising performance.Q: When is it recommended to choose PTFE Graphite Vacuum Systems?

A: They are ideal for situations requiring exposure to corrosive chemicals, high or fluctuating pressures (up to 20 bar), and temperatures from -200C to +260C, particularly in chemical, pharmaceutical, and industrial vacuum applications.Q: Where can PTFE Graphite gaskets be installed?

A: These gaskets are adaptable for use in vacuum pumps, chemical reactors, pipeline systems, and pharmaceutical processing units. Their customizable dimensions allow seamless integration across diverse equipment and settings.Q: What is the process for customizing the size and shape of PTFE Graphite Vacuum System components?

A: Manufacturers in India offer custom fabrication servicesclients specify dimensions (width up to 1000 mm, length up to 10 meters, thickness 15 mm) and preferred shapes (gasket, sheet, or special cut). The product is then engineered to these precise requirements.Q: How does the PTFE Graphite material ensure corrosion protection?

A: PTFE Graphite is inert to most chemicals, acids, and alkalis throughout the full pH range (0-14), excluding molten alkali metals and elemental fluorine. This exceptional inertness prevents corrosion, safeguarding equipment over extended use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PTFE Products Category

|

GRAPHICARB PRODUCTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry